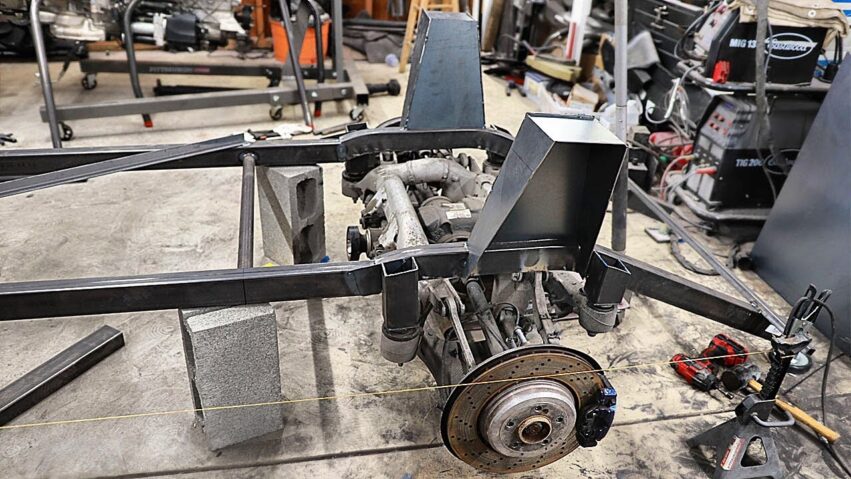

In todays episode we build the second strut tower and then weld in the subframe mounts and test fit the M5 subframe onto our 240z chassis!

❱ Shop – http://bisforbuild.com/#shop

❱ Patreon – http://www.patreon.com/user?u=3364742

❱ Facebook – http://facebook.com/bisforbuild

❱ Instagram – http://instagram.com/bisforbuild

❱ Twitch – https://www.twitch.tv/bisforbuild

Music:

Fareoh – Cloud Ten

Rb26dett or rb25dett still would have been better but damn there is a lot of work in this

Building cars is a three way thinking process sometime four or five. You got to love it I've been working with cars since my dads farm I can pretty much fix most things bush hogs planters fences electric systems plumbing my dad taught me a lot his idea of a vacation was more work I don't think he ever stopped we owned a Volvo dealership so if we weren't working now I'm disabled and it sucks I get bored easy I can't compeat but I can fix anything pretty much

you should definitely tidy that place up.

I guess in hindsight you could have made the strut tower pieces in pairs.

"Rear negative jig" Go Binky!! 😉

please place the video in order to be easy to follow from scratch

Really respect all your work, but darn that frame looks flimsy.

No way I'd be drifting that Z hard over curbs.

Looks like Chinese imitation metal or something 🙂

I don't usually comment on videos, but I wanted to commend the attitude. The first car I watched you build was the Plan B BRZ, and in those days I remember you working outside in the rain and still getting things done. I love the channel and love the energy you put into every single build. So good to see you're still motivated on the 240. Keep it going!

Try to get your current Z shell fixed/straightened. It'd be a shame to chop up a second Z, especially a real nice one, and have your shell scrapped. Besides, all the structural rigidity is going to be in your frame, so as long as the body looks straight it shouldn't matter that much.

How much is the rx7?

FYI dude, from my experience in Oregon, you'll have to fight the insurance every step of the way to keep the claim process moving, and especially when you don't agree on the payout amount. Don't be afraid to push them to move faster and accept your offer! You have the power as the damaged party, and they have to make you whole quickly (possibly 30 days if I remember correctly). File a complaint with the state insurance division if you have to, when I did this they called within a day and offered me everything I was asking for.

Smashed it ten times!!

Why does this channel have like 10x more ads than other channels?

Why didn’t you lower the frame to the sub frame lol would of been much lighter to move the frame and less load on it bending under weight?

Keep it up it makes good watching 😂

Hey Chris, did you check if the strut towers will fit the 240z body. Maybe you could use the danaged body for testfitting… greeting from Holland.

is this 240 ment to be a monster truck? look at how high the frame is in comparison to the wheels… it's shocking tbh

PLZ go back to the whi nu whi nu music!! so much better

Really hope you win the Gran Turismo Award in SEMA, you deserve it!!! Also, it'll be cool to drive your car in the game!!!

Im really excited for this build

Im really excited for this build

Im really excited for this build

Chris can you send me your email, i have maybe solution for mounting rear subframe, or if anybody know how can i get in contact with chris?

Why do you need to weld in the subframe centering posts? You could cut them to length and leave them in the subframe holes and they will insert themselves into the frame mounting locations as you tighten the bolts. Once everything is torqued they won't really matter if they're welded or not. This leaves you with options for adjustment if needed down the road. Maybe i'm missing something but I don't see why they need to be welded.

I'm a little concerned about the main frame rails, they seem a little bit to high. I would think they would need to be at or below the centerline of the hubs.